Sinter Plant Project

Sinter Plant Project

Project Overview

Comprehensive structural steel fabrication and erection for Shyam Sel & Power Ltd..

Client Name

Shyam Sel & Power Ltd.

Location

Jamuria , Asansol (West Bengal).

Project Area

37,500 Sq Mtr

Capacity

1.20 MTA 1.5 MTA @4535 With 335 working Days

Duration

2 Years

Steel Tonnage

6,000 MT

Sinter Plant Structure Fabrication & Erection with Equipment

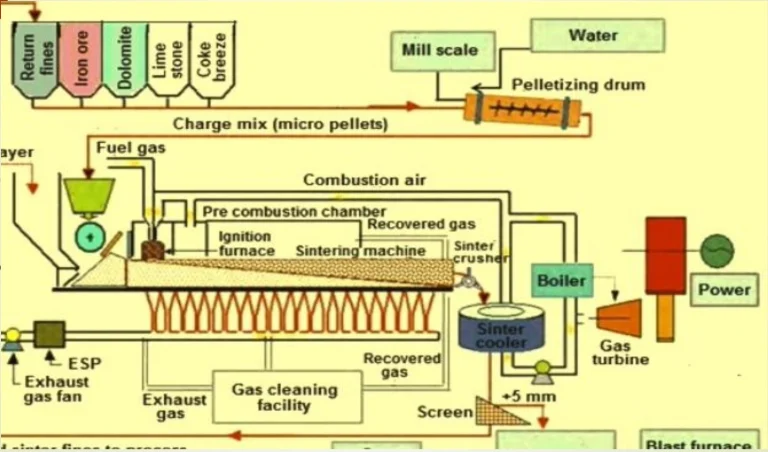

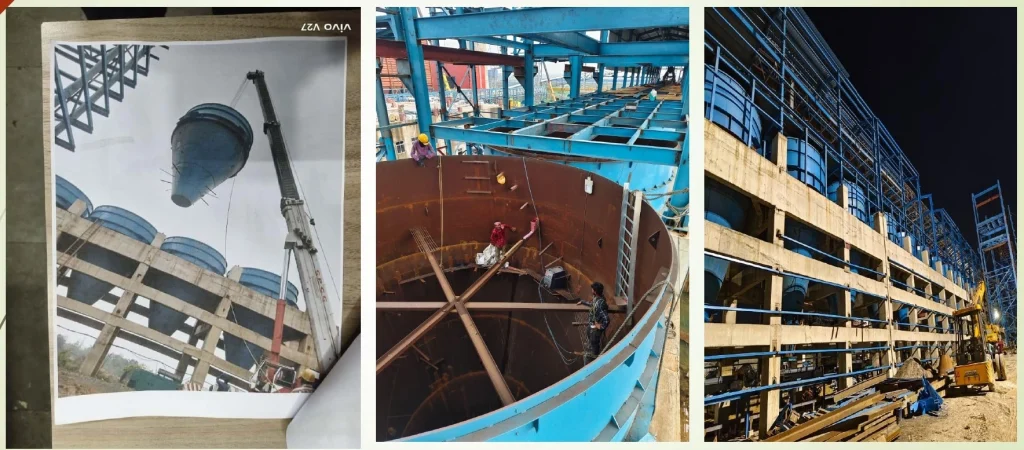

- The project involves the fabrication and erection of a 125 sq. meter Sinter Plant, including all major structural, mechanical, and ducting works. The scope covers the complete fabrication, assembly, and Erection of key units such as the Sinter machine, Screen Building, Primary Mixing Drum, Secondary Mixing Drum, ESP Duct, Main ID Fan Crusher Building and auxiliary structures.

- Fabrication activities include cutting, welding, machining, and assembly of steel structures, ducts, hoppers, bins, chutes, platforms, and supporting frames as per approved drawings and quality standards. All fabricated material is subjected to strict inspection and testing before Erection.

- Erection work comprises lifting, alignment, bolting, and welding of the fabricated structures and equipment using cranes and rigging tools, ensuring dimensional accuracy and safety compliance. The project also includes alignment of rotating and static equipment, duct routing.

- The entire fabrication and erection process is executed under stringent safety, quality, and environmental standards, ensuring timely completion and readiness for commissioning of the 125 sq. meter Sinter Plant.

Project Scope

The Scope of work covers the complete fabrication & erection of Structure steel, Head ESP, Tail ESP Duct & Pneumatic works and Related its Equipment.

- RAW Material Proportioning Bins – Structural fabrication & erection for Proportional Building including Bins, Shed, Monorail, Platform and including its Equipment.

- PMD – Fabrication & Erection of Primary Mixing Drum Shed,Monorail & maintenance Platform.

- SMD – Fabrication & Erection of Secondary Mixing Drum Shed, Monorail and Maintenance Platform.

- Sinter Machine – Heavy Section Structure designed for the Cooler equipment, EOT Cranes, Walkway, Platform.

- Wind Boxes with Waste Gas – Fabrication & erection of round Duct of 4.4 m Dia With 63 meter long for waste gas, Dust transfer to ESP with the help of Main ID fan and its Hoppers & Platform.

- Single roll Crusher – Construction of Steel Structure for Single Roll Crusher and its Platform, Monorail.

- Cold Screen – Fabrication & erection of Hollow pipe Structure for installation of Cold Screen, EOT Crane & Platform.

- Conveyors,receiving & transfer Chute for Raw Materials – Fabrication & erection of Technological Structure including Conveyors, Chute & its Equipment’s.

- Tail Esp – Fabrication & erection of Duct and its Support Structure for Tail ESP Dedusting along its Equipment.

- Head ESP – Fabrication & Erection of Head ESP Inlet & Outlet Duct with its Support Structure.

- ID Fan – Construction of Steel Structure for Main ID fan Installation, EOT Crane, Walkway & Platform.

Site Selection For Fabrication Yard

Advantages of selected site – Location criteria.

- Water requirement

- Power requirement

- Raw materials requirement

- Land Availability

- Temperature Condition

- Waste disposal

Raw Material Proportioning

The raw materials are stored in the bunkers. Description : Bunkers 1 to18 the raw Material are Stored in the Bunkers.

- Bunker 1 to 6 – Iron Ore Fine

- Bunker 7 – Mill Scale

- Bunker 8 – ESP Dust

- Bunker 9 – Quick lime

- Bunker 10 – Quick Dolo

- Buker 11 to 12 – Coke Fine

- Bunker 13 to 14– LimeStone Fine

- Bunker 15 – Dolomite Fine

- Bunker 16 – Return Fine

- Bunker 17 to 18 – BF Return

Material are Proportioned in the ratio to obtain desired Sinter Chemistry & extracted with the help of Weigh Feeder/ Round disc feeder & fed in to the main Conveyer.

Manpower and Training

Organization structure

• Manpower requirements: skilled, semi-skilled, unskilled example –

| S.No. | Description | Number |

|---|---|---|

| 1 | Site Incharge | 1 |

| 2 | Project Co-ordinator | 1 |

| 3 | Project Engineer | 2 |

| 4 | Supervisors and Safety Officer | 6 |

| 5 | Foremen/Fabricator | 3 |

| 6 | Workers | 145 |

| 7 | QA/QC | 2 |

| 8 | HR | 2 |

| TOTAL | 162 | |