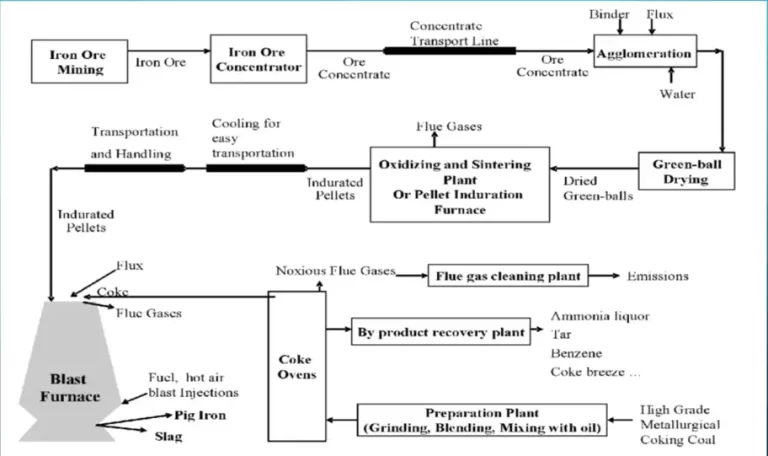

Blast Furnace

Blast Furnace

Project Overview

Comprehensive structural steel fabrication and erection for Shyam Sel & Power Ltd.

Client Name

Shyam Sel & Power Ltd.

Location

Jamuria , Asansol (West Bengal)

Area Of Plant

47,500 Sq Mtrs.

Capacity

0.77 MTPA

Duration

1.5 Years

Project Title

Blast Furnace

Blast Furnace Structure Fabrication & Erection With Equipment

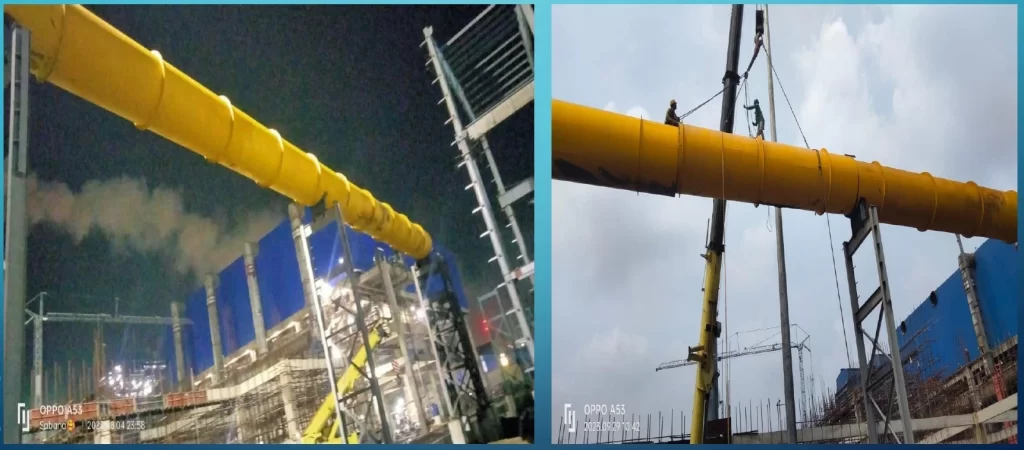

- The project involves the fabrication and erection of a 0.77 MTPA Blast Furnace, including all major Duct, structural, mechanical works. The scope covers the complete fabrication, assembly, and Erection of all high- Pressure Duct and its related equipment.

- Fabrication activities include cutting, welding, machining, and assembly of steel structures, ducts, platforms, and supporting frames as per approved drawings and quality standards. All fabricated material is subjected to strict inspection and testing before Erection.

- Erection work comprises lifting, alignment, bolting, and welding of the fabricated structures and equipment using cranes and rigging tools, ensuring dimensional accuracy and safety compliance. The project also includes alignment of rotating and static equipment, duct routing.

- The entire fabrication and erection process is executed under stringent safety, quality, and environmental standards, ensuring timely completion and readiness for commissioning of the 0.77 MTPA Blast Furnace

Project Scope

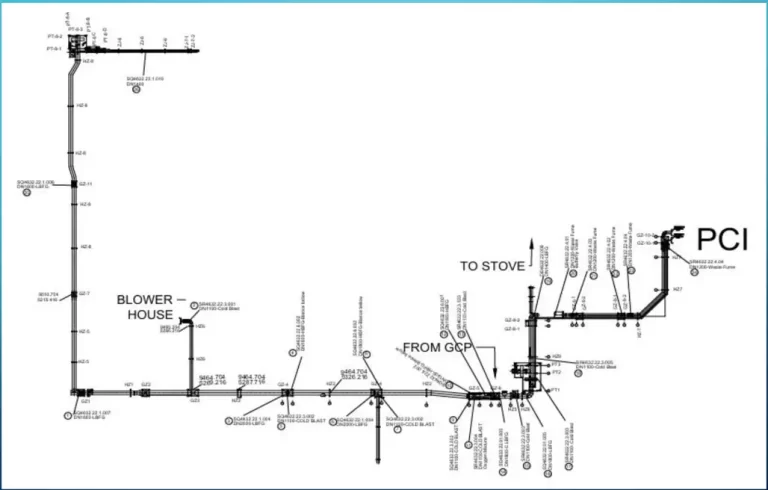

The Scope Of Work Covers The Complete Fabrication & Erection Of High Pressure Duct & Structure Steel Works And Its Related Equipment

- DN 1100 Cold Blast Pipe Line from blower house to Hot Blast Stove total in 185.502 Mtr.

- DN 1200 Waste gas Pipe line from Hot Blast stove to PCI total length 61.186 Mtr.

- DN 1800 High Pressure Blast line HBFG (Hot blast Furnace Gas) Connecting TRT Inlet gas line to gas purification outlet Purified gas pipeline total 93.2 Mtr.

- DN 1600 Low pressure Gas Pipeline from pellet Interface to DN 2000 total length is 295.3 Mtr.

- DN 2000 BFG Blast Furnace Gas total length is 315.5 Mtr.

- DN 800 Low Pressure Gas Pipeline from Blast Furnace to Sinter Machine Length is 162.34 mtr.

Site Selection For Fabrication Yard

Advantages of selected site – Location criteria.

- Water requirement

- Power requirement

- Raw materials requirement

- Waste disposal

- Easy Transportation(Nearby Highway)

- Humidity/Temperature condition

- Land Availability

Manpower and Training

Organization structure

• Manpower requirements: skilled, semi-skilled, unskilled example –

| S.No. | Description | Number |

|---|---|---|

| 1 | Site Incharge | 1 |

| 2 | Project Co-ordinator | 1 |

| 3 | Project Engineer | 1 |

| 4 | Supervisors and Safety Officer | 3 |

| 5 | QA/QC | 1 |

| 6 | HR | 1 |

| 7 | Fabricator | 1 |

| 8 | Workers | 62 |

| TOTAL | 71 | |