Cold Rolling Mill Project

Cold Rolling Mill Project

Project Overview

Comprehensive structural steel fabrication and erection for Jindal Steel & Power Ltd.

Client Name

Jindal Steel & Power Ltd.

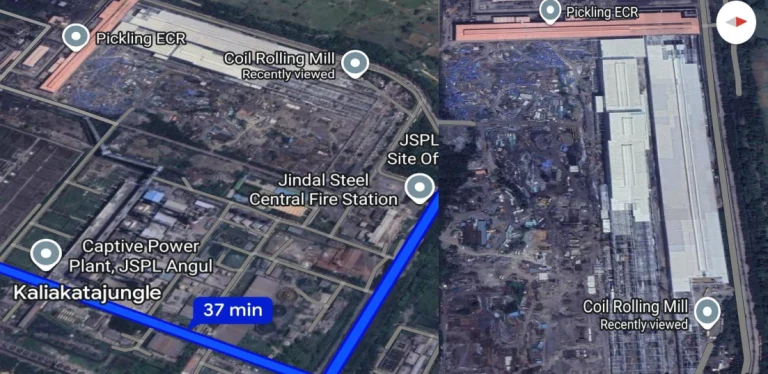

Location

Angul, Odisha.

Project Area

100,250 Sq Mtrs.

Capacity

1.20 MTA

Duration

2 Years

Steel Tonnage

6,000 MT

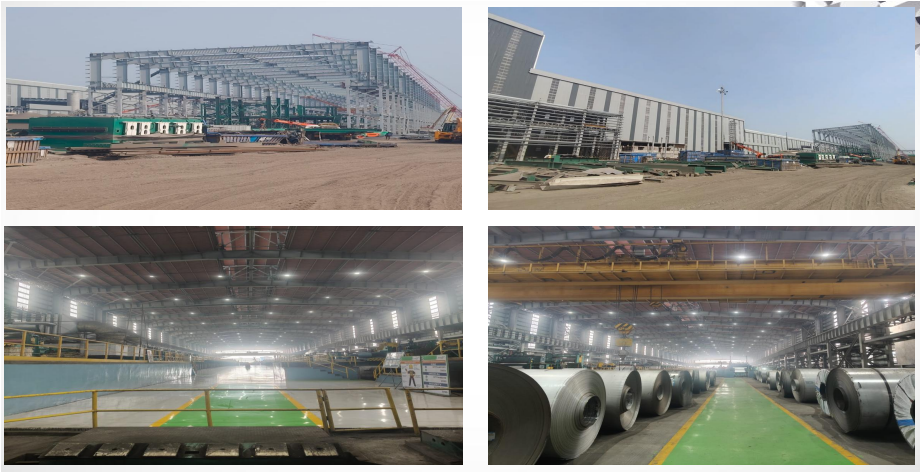

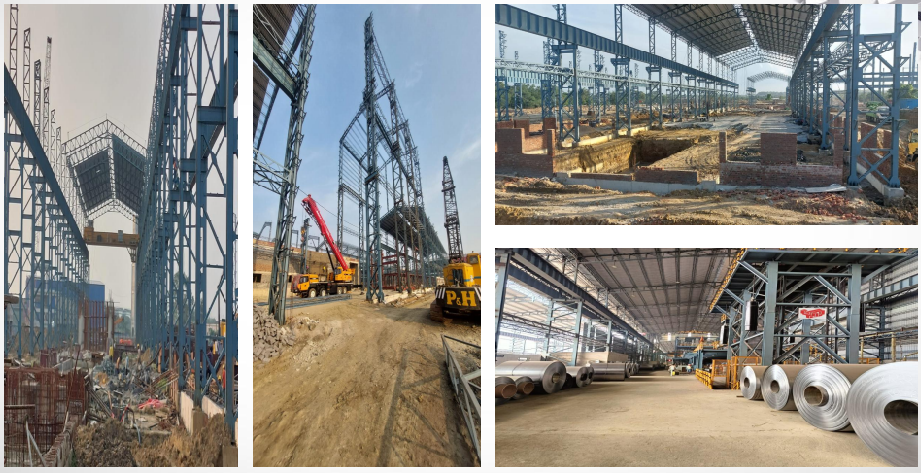

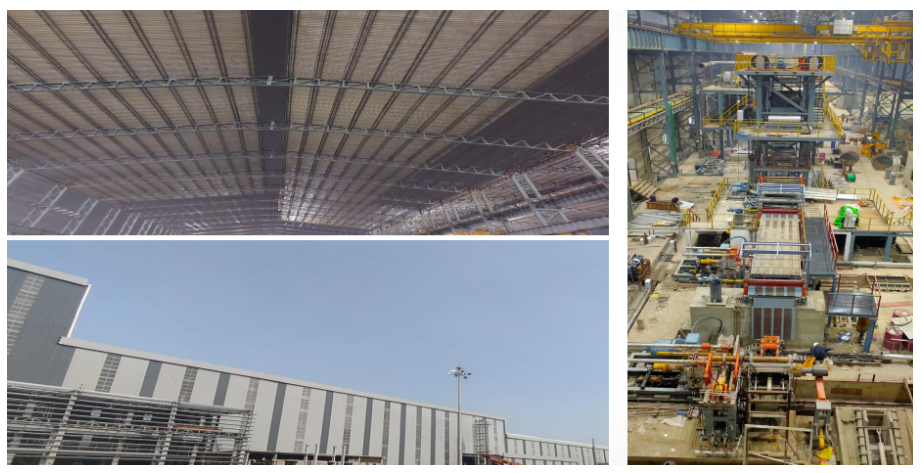

Brief Description of Project: Cold Rolling Mill Shed Fabrication & Erection

The project involves the fabrication, surface preparation, painting, supply, and erection of structural steel for the Cold Rolling Mill (CRM) complex, along with the installation of associated utility plants and pipelines. The total estimated structural steel tonnage is approximately 6000 MT.

Project Scope

The scope of work covers the complete fabrication and site erection of structural steel for the following major areas:

- Pickling & HRS Shed – Fabrication and erection of structural framework for housing the pickling line and cold rolled steel processing area.

- Mill Bay Shed – Heavy-duty structural shed designed for the installation of rolling mill equipment, cranes, and maintenance platforms.

- CCL 1250 & CGL 1500 Sheds – Structural fabrication and erection for Galvanizing Lines 1250 & 1500, including platforms, service structures, and crane supports.

- CCL & Finishing Shed – Construction of steel structures for Continuous Cleaning Line and finishing sections with walkways, access platforms, and service structures.

- H₂ Plant Installation (200 Nm³/hr) – Installation of hydrogen generation units including instrumentation pipeline work and required interconnections.

Site Selection For Fabrication Yard

Advantages of selected site – Location criteria.

- Water requirement

- Power requirement

- Raw materials requirement

- Waste disposal

- Easy Transportation(Nearby Highway)

- Humidity/Temperature condition

- Land Availability

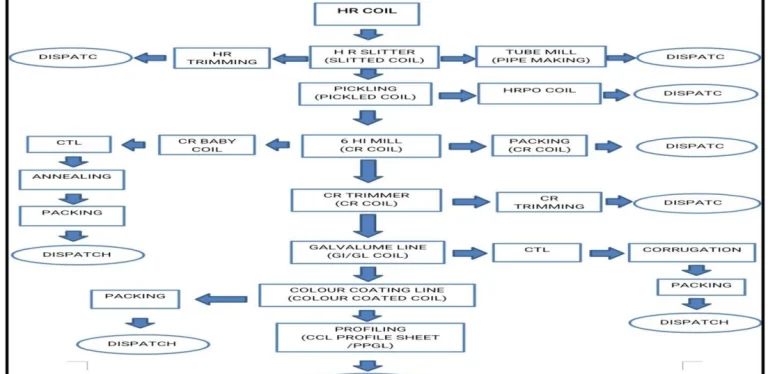

Equipment and Machinery In CRM Plant

Major equipment’s In CRM plant-

- HR SLITTER- 2000mm Width

- PICKLING LINE- 1500mm Width

- 6HI COLD ROLLING MILL- 1250mm wide @ 1200 MPM.

- CGL 1250 Width

- CCL 1500 Width

- TRIMMER Line – 1200 Wide @ 400 MPM

- TRIMMER Line – 1200 Wide @ 400 MPM

Manpower and Training

Organization structure

• Manpower requirements: skilled, semi-skilled, unskilled example –

| S.No. | Description | Number |

|---|---|---|

| 1 | Site Incharge | 2 |

| 2 | Project Co-ordinator | 1 |

| 3 | Project Engineer | 4 |

| 4 | Supervisors and Safety Officer | 16 |

| 5 | Foremen | 10 |

| 6 | Workers | 350 |

| 7 | QA/QC | 2 |

| 8 | HR | 2 |

| TOTAL | 387 | |